Cutting Edge Equipment

Our decision to invest in the best technology in the market today stems from our deep passion and aim, to be associated with some of the best quality glass fabricators within the industry. Not only do these technologies allow us to produce higher quality glass but also assist in meeting high demands, complete precision, shorten lead times, and run lean.

Hegla automatic Gantry Loading System

Automatic conveyor systems link the glass store with the cutting shop. The Hegla Gantry Loading System supplies the cutting lines continuously with glass. The rotatable Gantry Loading System can select from 45 different glass types from the storage area and place them at the front without the need for additional operator intervention. The maximum glass the cutting line can process is 108"x 144"

HEGLA cutting table

The Galactic float glass cutting machine with electromagnetic linear drives has a highly dynamic movement. In conjunction with the high resolution measurement system, these linear drives without mechanical gears set benchmarks in precision. The Galactic machine can cut a maximum size of 108" x 144" and is equipped with edge deletion for low-e glass.

GLASton FC500 Tempering line 110" x 192"

This engineering masterpiece was designed to temper all types of glass but specifically high performance low-e glass. On an average tempering line low-e glass would have a significant amount of distortion and roller wave. We take pride in knowing that we are able to surpass the strict tolerances and high quality glaziers and architects expect. We can temper a minimum size of 4" x 10" and a maximum size of 108" x 144".

GLASTON ilook and icontrol intelligence tempering line scanner

We are dedicated to pushing the envelope and setting new benchmarks in tempered glass quality. Coupled together the iLooK and iControl are the most intelligent and accurate online measuring system for world-class tempered glass quality. With these high tech systems we can accurately measure for roller wave and leading/trailing edge kink. Detailed reports can be provided to our customers for each lite of tempered glass to ensure we meet their quality specification.

Billco Horizontal Washer

The 600 series washer is equipped with 8 low-e safe brushes and 2 pairs of air knives to ensure absolutely spotless glass. We have also added a deionized water filtration system for ultra-purified water. The maximum size glass the washer can process is 109" x 144".

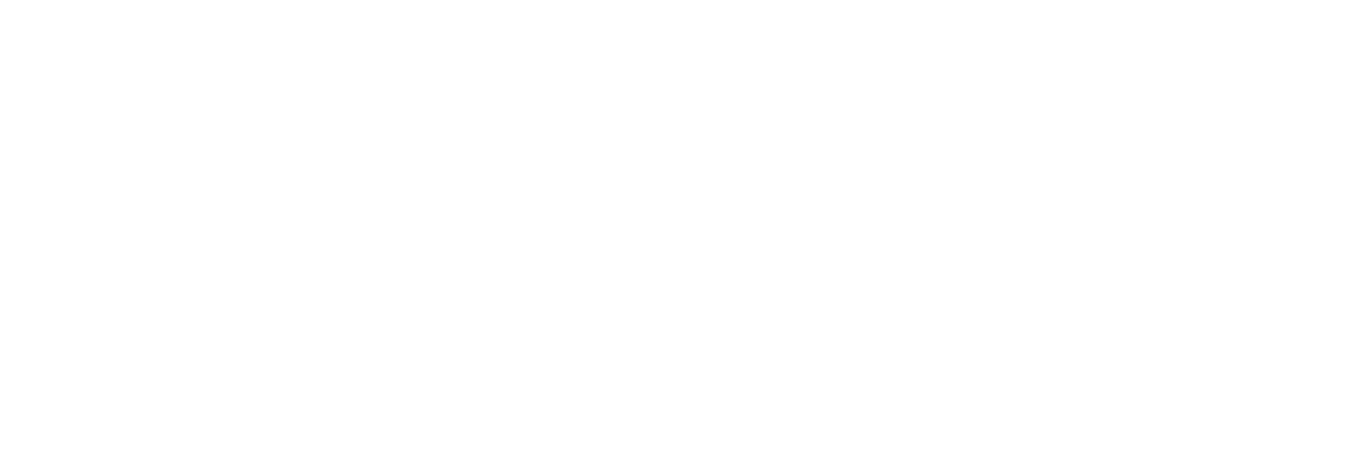

Bovone Straight Line Polisher

The ELB 10 is a 10 cup type wheel edger designed to produce precision flat edges with seams. The polisher consists of 5 diamond wheels for flat edge, 2 diamond wheels for seams, 2 composition type polish wheels for seams, and 1 felt wheel for cerium oxide polish for flat edge

BOVONE STRAIGHT LINE POLISHER and Miter

The ELB 10 is a 10 cup type wheel edger designed to produce precision flat edges with seams and miters. The polisher consists of 5 diamond wheels for flat edge and miter, 2 diamond wheels for seams, 2 composition type polish wheels for seams, and 1 felt wheel for cerium oxide polish for flat edge. The polisher is equipped to process up to 60 mm for laminated glass products.

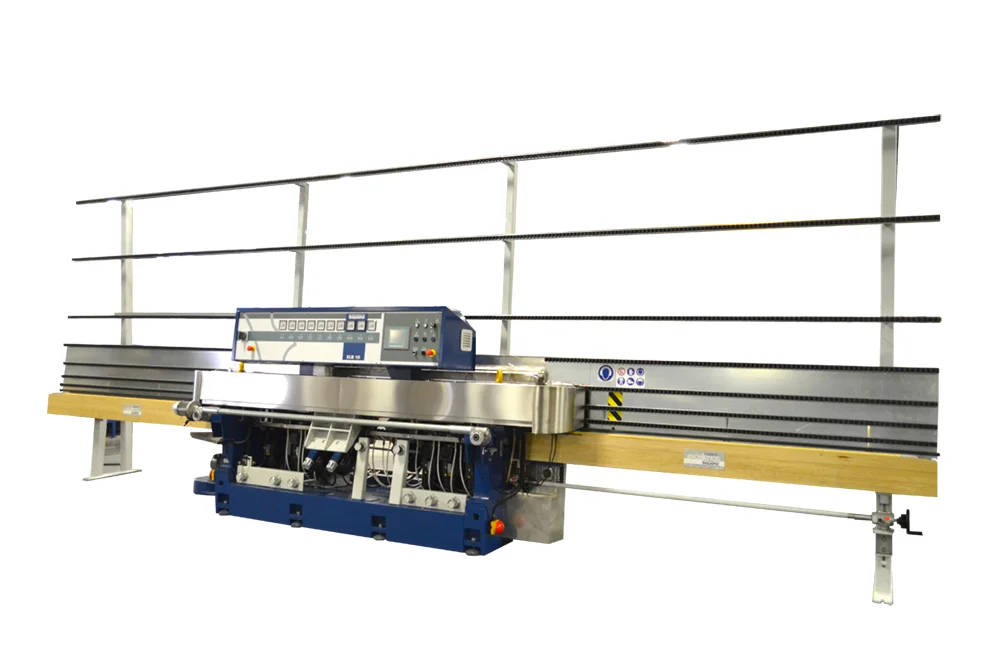

Forel automatic vertical drilling and milling

DM is the new series of high performance Drilling & Milling line from Forel. The machine is configured with two opposing heads and two tool storage units with 6 positions for execution of holes, notches, and cutouts. The two opposing heads ensures that the glass does not "blow out" while drilling. The vertical design allows minimal handling and faster processing times. The maximum size pane the machine can process is 98.4" x 177.1"

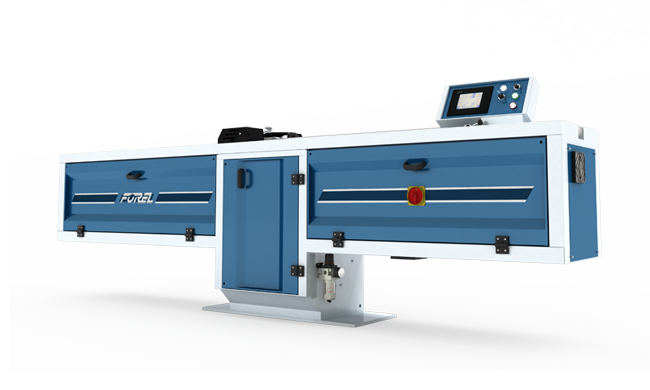

FOREL Insulated glass Line Vertical Washer

The VW series of washers represent the latest Forel evolution in the glass washing sector. The washer automatically recognizes low-E glass while each individual brush operates independently in order to enable proper cleaning of low-E panes. The unit is divided into 5 working stages: pre-washing, degreasing, washing, rinsing and drying. The high tech washer allows for absolutely spotless insulated glass units.

FOREL INSULATED GLASS LINE Coupling Press with gas

The APG series couples and presses double/triple glazed units and gas fills the cavity, automatically calculating the volume required. We can fill units either with Argon or Krypton. With its superior design the machine offers a very high fill percentage. The double/triple glazed unit is filled from the underside with an adjustable flow adapted to the IG unit dimensions. The minimum double glaze unit with gas size is 7.08" x 12.6" and the maximum is 98.4" x 126". For non gas filled units the maximum size is 98.4" x 177.1". The overall double/triple glazed unit maximum thickness is 3.15". The machine is capable of coupling, pressing, and gas filling offset units as well.

FOREL INSULATED GLASS LINE Automatic Sealing Robot

The automatic robot seals both double and triple glazed units with either silicone or poly-sulfide sealant. The precise sealing head uniformly distributes the sealant around the whole border of the double glazed unit. A specific knife touches up and finishes the corners. The automatic sealer can process regular or shaped glass. The state of the art automatic robot allows for consistent and high quality seals.

FOREL INSULATED GLASS LINE AUTOMATIC profile bender

The automatic spacer bend can process metal or composite material profile with thickness from .23” – 1.26”. Every operation is automatic including strip handling, joining and dual cutting. The machine can also bend spacers for shapes.

FOREL INSULATED GLASS LINE Desiccant loader

The desiccant loader drills the spacer frame externally using 2 drills set at 90° to enable the desiccant material filling, the 2 holes are then hermetically sealed by the application of butyl rubber. The spacer is drilled externally to leave the receiving walls intact. The desiccant loader can also process shaped spacers.

FOREL INSULATED GLASS LINe BUTYL EXTRUDER

The butyl rubber extruder applies a butyl rubber seal with a extruder nozzle on the entire perimeter of spacer frames. The butyl rubber flow is identical on both sides and adjusted by dosing units working in tandem

CHEMWEST PARTICLE REMOVAL System

The system is used for removing particulate and fines associated with the glass cutting. Our dedication to being an environmentally friendly company motivated us to invest in a closed loop water filtration system which significantly reduces water waste.

Optima ERP System

We know being data driven is required to run a efficient and responsive production, that's why we have invested in Optima glass software solutions. The enterprise resource planning system allows us to streamline our entire process from quotation to delivery. The software has several functions such as capacity planning, order tracking stations, dynamic optimization tools, inventory control, CAD/CAM drawing system, and quick quotation.

ENCLOSED Glass Truck

We know how important it is to get your glass delivered on time and in perfect condition. Our custom built enclosed delivery trucks protect your glass from debris and elements. We do daily local delivery in New York and New Jersey. We also deliver to non-local customer in neighboring states.